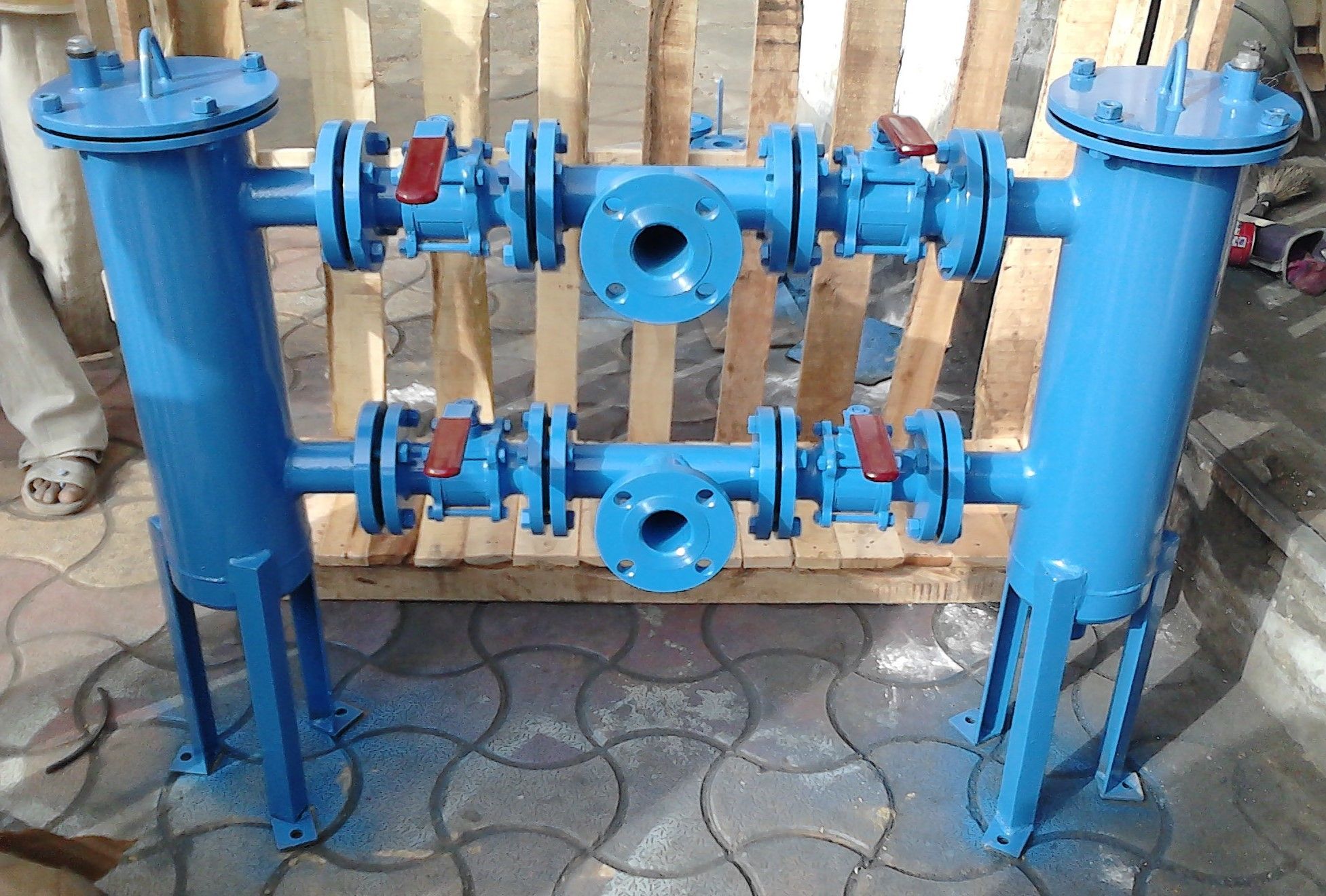

Duplex Filter Housing

Product Details:

- Weight 20 Kilograms (kg)

- Length 35 Centimeter (cm)

- Width 120 Centimeter (cm)

- Height 40 Centimeter (cm)

- Product Type Duplex Filter

- Color Blue

- Usage Liquid Filtration

- Click to View more

Duplex Filter Housing Price And Quantity

- 25000 INR/Piece

- 1 Piece

Duplex Filter Housing Product Specifications

- Liquid Filtration

- Blue

- Other

- Cylindrical

- Cylindrical

- Duplex Filter

- CS, MS, SS304, SS304L, SS316, SS316L, SS317L

- 1 Micron to 6000 Micron & More

- New

- Others

- 40 Centimeter (cm)

- 120 Centimeter (cm)

- Other

- 35 Centimeter (cm)

- 20 Kilograms (kg)

- 50 Centimeter (cm)

Duplex Filter Housing Trade Information

- Gujarat

- Cheque Cash in Advance (CID) Cash Advance (CA)

- 5 Piece Per Month

- 2 Week

- Sample costs shipping and taxes has to be paid by the buyer

- Wooden Box

- Assam Chandigarh Himachal Pradesh Andaman and Nicobar Islands South India Central India Chhattisgarh Daman and Diu North India East India Arunachal Pradesh Goa Haryana Kerala Jammu and Kashmir Jharkhand Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Nagaland Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Uttarakhand Dadra and Nagar Haveli Lakshadweep Uttar Pradesh Delhi Gujarat Bihar Andhra Pradesh Odisha West India Karnataka All India

Product Description

Duplex FilterStrainer is used for continuous operationwithout stoppage of filtration process Duplex filter is also known as oneworking and one stand by filter Duplex Filters are available with Three wayball valve two way ball valve and butterfly valve Filter elements are easy toremove and clean We offered duplex filter with flow direction in to out or outto in as per dirt load and application We also offer back wash arrangementOur Duplex filter in MSCS MOC is available with Painted hot dip galvanizedand powder coated Duple filter in SS MOC is available with mirror polishedboth side and glass bead blasting

Duplex filter design available with us

Duplex Basket Filter

Duplex Multi Basket Filter

Duplex Pleated Basket Filter

Duplex Single Cartridge Filter

Duplex Multi Cartridge Filter

Duplex Candle Filter

Duplex Bag Filter

Duplex Multi Bag Filter

Duplex Strainer

Duplex Basket Strainer

Duplex Type Self Cleaning Filter

Jacketed Duplex Filter

Technical Parameters

Line Size NB to 30 NB

End Connections 150 300 Flanged Table E Table F Flanges DIN Standard Flanges Butt Weld

NPTBSPThreaded Hose Pipe Conn Tri Clover Adaptor SMS UnionDairy Conn

Material of Construction CS MS SS304 SS304L SS316SS316L SS317L

Operating Pressure 0 to 50 Bar

Operating Temperature 15 Deg C to 500 Deg C

Flow Rate Up to 1000 M3Hr More

Filtration Rating 05 Micron to 6000 Micron More

Top cover with nut bolts type or quick opening type

Advantages

Easy to clean

Low Pressure drop

Large area

Easy to operate and maintenance

Positive Sealing to prevent bypass

Customized design

High dirt load holding capacity

In Standard design filtration area is 4 to 6times of InletOutlet pipe area

Arrangement for back wash if required

Applications

Refineries and Petrochemicals

Power Plants

Oil Gas

Water filtration and Cooling Towers

Chemical Industries

Automobile Industries

Steel Industries Metals Minerals

Textile Industries

Dairy and Food Industries

Dyes Inks and paints Industries

Cement Industries

Fertilizers Industries

Pharmaceuticals

Coolant Oils and Cutting Fluids

Call Me Free

Call Me Free